| |

SCIENCE, TECHNOLOGY AND THE ART OF FLUTE MAKING IN

THE EIGHTEENTH CENTURY

by Ardal Powell

Word count: 7250. Download size (text only): 51,000

bytes.

Author's note: This article first appeared in The

Flutist Quarterly 19.3 (Spring 1994). For the

present version dates and page references for articles

that were not yet published in 1994 have been supplied.

Author-date references are to publications listed

at the end of the essay.

TODAY'S FLUTISTS look back on Theobald Boehm's re-invention

of the flute in the middle of the last century as a

sensational triumph of scientific method in the then

relatively new field of acoustics. We might be surprised

to find that Boehm's inquiries were not conducted in

a rigorous scientific spirit (Rockstro 1890, para. 911),

but that he "finally called science to [his] aid" only

in 1846 and began to study scientific principles of

flutemaking and acoustics as opposed to simply pragmatic

ones (Boehm 1871, 12). Since the waning of the seventeenth

century, when science had first become a model for intellectual

activity and worked its way into many aspects of life,

the flute's design had been continuously subject to

change in a number of distinctive and cross-fertilizing

traditions. The rationalism which arose in the seventeenth

century took two full centuries to work out its effect

on the flute, and it has taken still longer to bring

about the general acceptance of the Boehm flute and

the relative uniformity in instrument and playing technique

that we see today.

I. SCIENTIFIC WRITINGS

The first attempts to formulate "scientific" laws of

tube acoustics and to apply them to the flute were made

during the Enlightenment. Johann Heinrich Lambert's

1777 essay dealing specifically with the acoustics of

the instrument of that period may perhaps have been

written at the personal instigation of Frederick the

Great, who was deeply involved with current ideas as

well as with the flute. Lambert's paper attempts, in

the classic manner so succesful with astronomy and physics,

to deduce natural laws from practical experiment, using

the tools of minute observation and mathematics. He

gives a critical survey of previous work on acoustics

by Euler (1725) and Bernoulli (1762), and makes precise

measurements of his own flute, which produces a pitch

of a=415.25cps, as opposed to Bernoulli's standard of

a=392cps. He reports on basic experiments and calculations

with tubes; gives precise details of lip placement (half

the embouchure hole should be covered) so as to arrive

at a mathematical constant for the end correction of

the embouchure hole; and studies the effects of cork

placement. Remarks on his own flute refer to the relationship

of tonehole size to bore diameter, and the effect of

undercutting the toneholes (see below). Attempts like

Lambert's to describe the behavior of the flute in scientific

language continued into the nineteenth century with

works of Johann Heinrich Liebeskind (1806), Heinrich

Wilhelm Theodor Pottgiesser (1803), and Karl Franz Emil

Schafhäutl (1833), Boehm's teacher in acoustics.

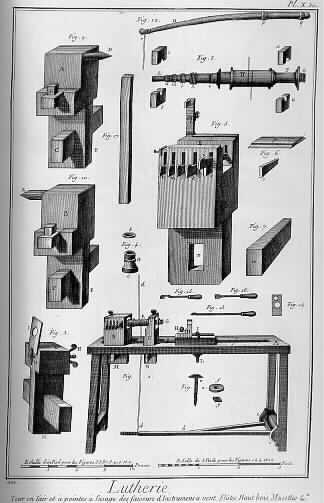

Figure

1. P.C. Plumier minime, L'Art de Tourner en Perfection,

Paris: Jombert, 1749, plate 1 Figure

1. P.C. Plumier minime, L'Art de Tourner en Perfection,

Paris: Jombert, 1749, plate 1

But the work of Lambert and other theorists serves as

a contrast to the lack of any significant technical

information about woodwind instrument building left

by the makers themselves. In this period Art, Craft

and Science were not as distinct as they are today,

and flute design was guided by a personal or regional

concept of the instrument's sound and character, and

by the current requirements of musical taste. Flute-makers

in this period had no call to write down their design

criteria or their thoughts about instrument-making.

For most of the century, the practice of writing technical

descriptions of design features in order to gain patent

protection for them would have seemed absurd: the best

protection was complete secrecy (Heyde 1993a, 599).

But the ideas of the makers are revealed in the instruments

they made. To equip ourselves to interpret these "documents",

we should be aware of the tools and working practices

of the times, and the circumstances and environments

of the individuals concerned.1

Musical considerations naturally had a most important

effect on instrument design, but are beyond the scope

of this article.

II. FLUTEMAKING METHODS, TOOLS AND ORGANIZATION

TOOLS AND MACHINES

The tubes of woodwind instruments were made on the lathe.

This machine, which was driven by a treadle as early

as the middle of the 13th century (McNeil 1990, 26),

is a device for rotating, or "turning" the workpiece

so that a hand-held chisel positioned by a toolrest

can be used to make it cylindrical. Two driving mechanisms

for the lathe were in use in the eighteenth century.

A simple kind, in which a cord wrapped around the workpiece

was attached at one end to the treadle and at the other

to a springy wooden pole, allowed only a limited number

of rotations in one direction before the tool had to

be removed and the workpiece left to wind up the cord

again by spinning in the opposite direction. A more

sophisticated variety with a flywheel could maintain

constant rotation in the same direction (Genta 1985).

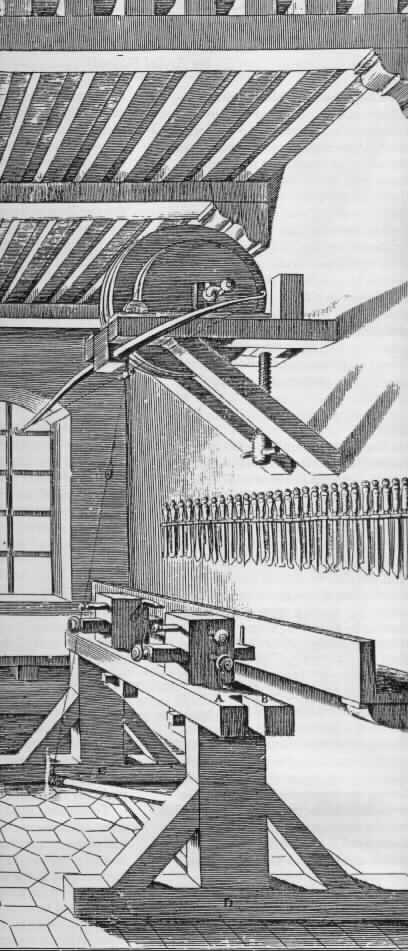

A machine with both a pole drive and a flywheel is shown

in Figure 1, but the example in Diderot's encyclopaedia

(Figure 2) is of the rather less advanced bi-directional

type. Devices existed to regulate the tension of the

flywheel's belt drive to adjust for changes in the air's

humidity, and to alter the turning speed with the same

treadle movement (Singer et al., Vol.5, 384). Still

more sophisticated machinery for ornamental turning

(Adkins 1990) existed throughout the period, but it

was probably rare in instrument-making shops.

Toneholes coul be drilled in the turned tube with a

strap drill (Singer et al., Vol.5, 381, Fig. 207-8).

By the second half of the century hand-braces with bevel

gearing existed, so that a drill could be rotated by

turning a handwheel at right-angles to the shaft of

the tool.

Figure

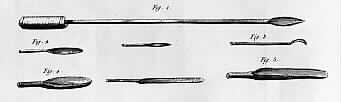

3. Reamers for woodwind instruments (Diderot 1781) Figure

3. Reamers for woodwind instruments (Diderot 1781)

Diderot's Encyclopaedia shows the reamers used

to make the internal bore of an instrument section (see

Figure 3), after a pilot hole had been drilled through

the center of the billet. While it is sometimes possible

to see marks showing that the bore was cut with a succession

of short reamers such as the ones shown, some makers

seem to have used a single-piece tool for each section

of the flute (Tromlitz 1791, 26-7). The advantage of

one- piece reamers is that mass-production of instruments

with identical bores is made faster and more reliable.

By minimizing variation this reduces the time taken

to finish an instrument.

The process of "finishing" a flute involved using files

and scrapers to shape and undercut the embouchure hole,

and to complete the tuning by undercutting the toneholes,

if necessary making small adjustments to the bore. As

Lambert observed (1777) the amount of wood removed from

inside each tonehole, and the precise shape of the resulting

walls, is a critical factor in the tone and response

of the instrument. Styles of undercutting range from

the almost imperceptible to cases where so much wood

is removed that the walls of the tonehole are invisible

from the outside of the flute. But because even very

small variations in undercutting can have such a large

effect on an instrument's playing qualities, files and

scrapers are not the most reliable tools for undercutting.

|

Figure 2. Wood turning shop (Diderot 1781)

|

An accurate and repeatable way to remove a determinate

amount of wood is provided by fraises. These are small

metal cutters passed up inside the bore and engaged

by a threaded rod through the tonehole to cut away its

underside. Various types were used by different makers.

August Grenser used fraises instead of scrapers and

files to undercut the toneholes of his flutes; others,

among them John Just Schuchart in London and Paul Villars

in Paris, used a combinbation of the two techniques.

One of the most effective ways to achieve consistency

and to speed up the finishing process is to develop

an instrument design in which undercutting plays little

part. By the time flutes with added keys had begun to

be accepted, tonehole undercutting was almost universally

much less than had been common on most one-keyed flutes.

The change in undercutting style went hand in hand with

a alteration in sound ideal, from fullness and resonance

toward brightness and penetration.

METALS FOR KEYS AND SPRINGS

A steady expansion in the mining of minerals other than

coal and iron took place in Europe between 1500 and

1750. Metallurgy developed from an art dependent on

trial, experience and rule of thumb into a combination

of art and science involving knowledge of the principles

underlying the behavior of metals.

The key of the one-keyed flute was usually made of silver,

a metal produced in Saxony, Bohemia and the New World.

The key was forged by hand out of a flat sheet, with

flaps bent over to take an axle pin on which the key

rotated. Keys made of brass, which had been developed

commercially in the previous century, become more common

on Continental flutes from the end of the period. The

ancient process of investment casting of brass greatly

reduced the work required to make keys, but it does

not seem to have arrived in flutemaking until around

1800.

The key, with its leather pad held on with sealing-wax,

was kept closed with a spring under its touchpiece.

In clockmaking, the introduction of the balance wheel

escapement by Hooke in 1656 made the production of reliable

springs an urgent priority. Well- behaved clock springs

were short-lived and hard to make, so that producing

them quickly became a highly specialised art. We have

eighteenth-century recipies for spring-making only from

the end of the century (Leutmann 1772; Blakey 1780),

when competition in the clock industry had become most

fierce, and it was in these times that the Swiss watchmaking

city of Geneva offered a prize to anyone who found a

way to make springs of comparable quality to the British

ones of crucible steel. This material, invented in c.

1740 by Benjamin Huntsman (1704-1776), the Doncaster

clock- and instrument-maker, was made at his Sheffield

plant under conditions of extreme secrecy. However it

is a measure of the contemporary lack of concern for

legal protection that he did not patent the process

and it was later copied by others, though only after

a monopoly of half a century.

Flute keys throughout the eighteenth century were usually

sprung with brass. At first the spring was attached

to the wood or ivory, with its free end in contact with

the metal key. But a thin piece of brass let into the

sides of the keyway had a tendency to work loose as

the wood expanded and contracted, and because the keyway

floor had to be lowered to accommodate it, and it exerted

pressure on the sides of the keyway, there was some

tendency for the wood to crack at that point. A more

secure and lasting way to fix the spring was to rivet

the brass to the touchpiece of the key, or sometimes

to fix it with a tiny watchmaker's screw. With this

method the spring hardly bends at all when the key is

depressed (Myers 1980, 59-60), and because of the reduced

mechanical displacement the spring feels less spongy

and lasts longer. Though fixing the spring to the key

seems to have been used on flutes as early as the 1730s

in Paris, it did not entirely supplant springs set into

the wood for at least half a century.

Leipzig virtuoso, teacher and flutemaker J.G. Tromlitz

was an advocate of steel springs, whose action on some

of his surviving instruments is more convincing than

his description:

The springs beneath the keys are made either of

brass or of steel. [Tempered] Steel or clock-springs

are more elastic, and consequently better, than those

of brass. They should not be set into the wood, but

riveted to the touchpiece, and allowed to contact

the wood. But since steel springs easily rust where

they touch the wood, they must occasionally be cleaned

and oiled lightly. . . Since a clock-spring has too

little strength under the key, especially if it is

long, you can put another, somewhat shorter one underneath

it, so that it is stronger and more elastic than a

single strong spring.(Tromlitz 1800, 138)

The invention of pewter plugs, cast to make an airtight

fit in a metal bushing let into the surface of the wood,

was intended to overcome the problem of leather pads

which became leaky after contact with oil or moisture.

They may well have been invented in England: the tin

which along with lead was an important component of

pewter had been mined in Cornwall since prehistoric

times. Tromlitz calls the pewter-plug keys "Tacett"

keys,2 and in 1794 J.F. Boie of Göttingen advertised

flutes made "after the masterpieces of Grenser

in Dresden and Potter in London", with the same

"very little-known invention of the Englishman Tacett".

3 But just a few years later in 1800, Tromlitz,

who found many faults with the device (Tromlitz 1786)

wrote (Tromlitz 1800, 139) that pewter plugs had "been

rejected for many reasons, and are now quite abolished"��a

premature obituary for a material that continued to

find favor, in London and Vienna at least, for many

decades.

GUILDS AND TRADE

As the astronomer Copernicus wrote: "The shortness of

life, the frailness of reason, and the dull routine

of senseless activity do not allow us to gain much knowledge.

And what we do learn we all too soon forget." Tradition

records that the stonemasons who gathered to build the

ancient Temple of Solomon were the first to form a corporation

or society to preserve specialised knowledge and skills

from one generation to another. In mediaeval Europe,

the principal crafts likewise became organised into

guilds, or self-governing associations holding the right

to conduct a trade under legal protection from competition

(Heyde 1993b).

Masters of a craft passed on their knowledge to apprentices,

who learned by repeatedly performing simple tasks, and

freeing the master's time to be spent where his skill

was best put to use, in finishing and tuning instruments.

After serving an apprenticeship, typically six or seven

years, an apprentice might work in the master's shop

as a journeyman, or "day-worker", until he was in a

position to open his own business, or succeed to his

master's.

By the beginning of the eighteenth century, trade activity

in most cities was governed by guilds. In eighteenth-century

Paris, two officers in charge of the Guild of Musical

Instrument-Makers administered its rules, which included

stipulations that only apprentices who had served six

years under a Paris Master, fulfilled their duties,

lived a moral life and paid their dues were entitled

to work for a wage; and that a Master might take on

only one apprentice at a time, until the apprentice

had studied four years, when an additional one might

be taken. Anyone who attempted to poach on the Guild's

territory would be punished by law, though internal

difficulties could also be caused by the strict closed

shop arrangement.4

Guild organization differed from one city to another:

Johann Christoph Denner, a Nuremberg maker who applied

to the town council in 1696 for permission to make the

new-style oboe and recorder developed in France (Nickel

1971, 204-5), was a member of the guild of Duck Call-

and Horn-Turners, though his son Jacob was disbarred

from becoming a master under the guild's strict moral

code because of his "shotgun" marriage (Kirnbauer &

Thalheimer 1995). In Leipzig, instrument making seems

to have been a "free trade", and it appears there was

no guild for woodwind makers at all. The activities

of merchants like Matthaus Hirschstein and the city's

annual trade fair provided an essentially continental

market for Saxon wind-instruments (Heyde 1985).

The craft of woodwind-instrument making benefited directly,

both in the development of materials and in workshop

techniques, from the diversification and growth in demand

for scientific instruments during the late seventeenth

century. In this period these sophisticated precision

tools began to be made by mass- production (Singer et

al., Vol.4, 629).

Figure 4. Batch marks in a flute by F.G.A. Kirst (St

Petersburg 1136)

Figure 4. Batch marks in a flute by F.G.A. Kirst (St

Petersburg 1136)

In flutemaking workshops, mass-production techniques

were used from the earliest years of the eighteenth

century. Inventories of the Paris workshops (whose documents

have been most closely studied in modern times) show

that large numbers, sometimes hundreds, of flutes were

in production at the same time. 5 Flutes from the workshop of Thomas Lot (fl.

1734- 1787), though not all identical in appearance,

show very small differences in essential measurements

over the large number of flutes that have survived,

indicating that the same workshop standards for many

stages of production were in force over several decades.

Roman numerals carved in the tenon ends, ivory mounts,

keys and keyways of flutes by J.J. Quantz, F.G.A. Kirst

and August Grenser (see Figure 4) are batch numbers

to help identify the parts during production, indicating

that the instruments to which they belonged were made

in a series. Surviving Quantz flutes are functionally

identical, as are a certain number of those by August

Grenser and many of Lot's.

The London makers of the latter part of the period not

only had a progressive approach to the division of labor,

but they also benefited from the British preeminence

in industrial production of high quality steel for tools.

Small files were mass-produced in Prescot and were readily

available in London. Labor was divided not just within

the workshop but farmed out to specialists, and so in

this period a maker's stamp is no certain indication

of who made which parts of the instrument; dealers and

even teachers seem to have stamped instruments made

by others with their own names. John Hale, (fl. 1785-1804)

whose name appears on a number of surviving flutes (Young

1982), made keywork in brass and silver for woodwind

instruments by Cahusac and Collier (Byrne 1964), flutes

by Joseph Florio, Richard Potter (Waterhouse 1993, s.v.

Hale), [Proser,] and one dated 1769 by Caleb Gedney.

Figures available from the clockmaking industry provide

a clear illustration of the economic effects of the

move from workshop to factory production (Landes 1983).

In the last quarter of the century, Britain produced

150,000-200,000 watches a year, half the total for all

of Europe. Small shops in the North of England made

rough actions, and sold them in quantity to London shops

for finishing. As a result, a watch movement that had

cost �20 a century earlier was now reduced in price

to �1. The boom in the flute's popularity in late eighteenth-century

England would not have been possible without similar

effects of increased production and falling prices--or

without a surge in the size and prosperity of the upper

middle class, associated with the success of the British

navy and the expansion of British trade.

In 1796 a rare written mention of the mass-production

of flutes occurs, in a piece of sales literature by

Tromlitz:

Those who employ a number of people, and have

their wind-instruments made by their journeymen and

apprentices, can of course offer them cheaper than

I, who do everything myself, and have to do it myself

if it is to be what I advertise. Such factory-made

instruments cannot possibly be what they should be;

this is easy to understand, and yet there are people

who think the opposite.

Tromlitz evidently considered the factory system to

be normal among contemporary instrument-makers, a class

from which he wished to exclude himself:

To classify me as an instrument-maker is not correct,

for I am not one; I only make instruments as a scholarly

musician and flute-player. I do not know any of the

ordinary instrument-makers who works from principles,

all just imitate, inside and outside Germany. Therefore

such flutes are only usable in a few keys. (Tromlitz

1800, 133)

III. CHANGES IN THE DESIGN OF FLUTES

During the early eighteenth century the flute rose to

be the most popular of wind-instruments. Its expressive

potential surpassed that of the recorder from the first,

but it was not as easy to play in tune, and the player

needed a command of embouchure and breath control as

well as tonguing and fingering. The inexhaustible diversity

of surviving instruments demonstrates that makers were

continually trying to increase and refine the flute's

ability to be expressive. Changes in musical composition

and performance made changing demands on the type of

expressivity the instrument was required to produce.

At the same time the flute was attracting a large number

of amateur adherents, who required that it be made easier

to play audibly and in tune. These are the major reasons

for the constant experimentation of the eighteenth-century

flutemakers.

The "baroque" flute had a conical bore as its distinguishing

feature. It is the bore's degree of taper and how regularly

or irregularly it contracts that determine the basic

visual and acoustic proportions of the instrument: the

length of the tube, and the size, position and undercutting

of the toneholes. For at least the first sixty years

of the eighteenth century all makers were experimenting

with the bore, in conjunction with other aspects of

the flute: the size, undercutting and spacing of embouchure

and toneholes, and the materials and wall thickness

of the tube. Even in the same city at the same period

no theoretical standard existed for many important aspects

of flute design: often makers had different approaches

at various points in their careers, evidently with dissimilar

results in mind. As a result the flutes of the eighteenth

century, even before the addition of keys, are acoustically

and functionally very diverse (Spohr 1992).

Two surviving instruments with slightly conical bore

and a single key prefigure the arrival of the true conical

bore: an anonymous one of unknown origin (Puglisi 1984),

and one by Richard Haka (Amsterdam: 1646-1705) (Solum

1993). Of the true three-joint baroque flute itself

we have two dozen surviving examples by makers from

Berchtesgaden, Berlin, Leipzig, London, Nuremburg, and

Paris (Powell and Lasocki 1995), each of whom had a

strong personal style and very highly developed skills.

Though the "Hotteterre" style instrument is generally

cited as the archetype of the early baroque flute, it

is by no means certain where or precisely when the three-joint

instrument with a conical bore and one key first appeared

(see note 8 below).

The process of designing wind-instruments is illustrated

by a description of the development of the recorder

and oboe in France in the 1680s, by the famous flutist

Michel de la Barre:

...the Filidors and the Hautteterres. . . spoiled

so much wood and played so much music that they finally

suceeded in making [the oboe] usable in ensembles.6

The statement supports what we can learn by studying

surviving three-joint instruments, which are quite different

from one another: that each maker arrived at the design

of his flutes by independent experiment.

In his autobiography J.J. Quantz describes the state

of composition (outside France) for the flute in the

years before 1720:

At that time there were few compositions written

especially for the flute. One had to make do for the

most part with compositions for the oboe and violin,

which one had to arrange as well as possible for one's

purpose.7

An obstacle to playing oboe or violin music on the flute

was that the flute's low register ended at D'. Downward

extensions of the range were hailed as a novel invention

by London flutemakers John Mason and Caleb Gedney in

1756.8 But a response to their claims by another London

maker, Charles Schuchart, shows that such extensions

had been known to his father John Just in Germany before

1720. Independent confirmation that they were used in

England is given by visitors to Pierre Jaillard Bressan's

shop in London in 1725 (Byrne 1983), and in Germany

by an illustration in Majer's 1732 treatise and a mention

by Quantz (1752, 34). A sole surviving such instrument

by Jacob Denner, with a low C but no C#, is in the Germanisches

Nationalmuseum in Nuremberg; a second one has gone missing

from the Berlin museum. Such lower extensions could

have been quite widely practised, but did not catch

on.9

Around 1720 the three-joint flute was divided into four.

The long middle section with six holes was replaced

by two shorter ones, joined by a tenon and socket in

the middle, and having three holes each. Why, and precisely

when and where this occurred remain uncertain. The event

was first mentioned by Quantz, who wrote in 1752 that

it had taken place "about thirty years ago".10 According to Quantz, the purpose of the division

was to allow interchangeable middle joints, or corps

de rechange, to vary the pitch of the flute, but

this explanation has been questioned since 1791 (Tromlitz

1791, 25). A four-joint flute by Amsterdam maker Thomas

Boekhout, now unfortunately lost, was catalogued in

1922 (Sachs 1922, 1.643), and since Boekhout's business

shut down when he died in 1715, it is possible that

flutes in four sections were made half a decade before

Quantz, still principally an oboist at the time, got

to hear of it. The division had the effect of allowing

the maker greater access to the central part of the

bore (Powell 1995): whether this was cause or effect,

enlargements of the bore at the top of the heartpiece

are found in some early 4-joint flutes, a further sign

of experimentation.

The possibility of supplying corps de rechange

to alter the pitch is first documented in a promissory

note from the flutist Desjardins to the widow Naust

dated December 30th 1721, referring to a flute with

three "cors"(Giannini 1993, 9). At least two

Paris makers were accustomed to making instruments for

use in other cities where different pitch standards

were in use: J.J. Rippert made instruments for customers

in London and Frankfurt, with those made for London��to

supplement ones by Nicolas (Colin) Hotteterre already

in use��tuned to the higher pitch standard there (Giannini

1993, 44-46 n.11). As more and more establishments began

to adopt the higher of two common chamber-music pitches

(a=408-415cps) in preference to the lower (a=390-400cps),

makers were faced with the problem of reinventing the

instrument to work well at the higher pitch, or even

to work well at several pitches. The earliest dated

instrument with corps de rechange to survive

to the present is one stamped "1736" by Charles Bizey

(Paris: fl. 1716-1753) in the Germanisches Nationalmuseum

in Nuremberg.

When changing the pitch of a flute by replacing the

upper middle joint with a longer or shorter one, it

was necessary to move the cork in or out in relation

to the embouchure hole so as to keep the octaves in

tune (Quantz 1752, 32; Tromlitz 1791, 32-38). The first

mention of a screw device for moving the cork is by

Quantz (ibid.), at which date he also refers

to the invention of the foot-register "not very long

ago" (op. cit., 33). Antoine Mahaut claimed that

both were invented by Quantz's teacher, the Royal Saxon

flutist Pierre-Gabriel Buffardin, not known as a maker

himself (Mahaut 1759, 1). Tromlitz claimed to have made

independent improvements in the devices, such as adding

a gauge to the screw-cork to indicate its position,

but he may not have been the first to do so. And the

screw-cork and register were not in universal use: Thomas

Lot (Paris: 1708-1786), whose workshop made instruments

for countless fashionable and noble customers, as well

as for flute virtuosi Blavet, Philidor, Piéche,

Naudot and Wendling, (Giannini 1993) is survived by

thirty-one flutes, not one of which is equipped with

screw-cork or register.

Another innovation which did not gain general acceptance

was the D# key. Quantz had such a key added to his flute

while in Paris in 1726, and though he explains the reason

for this in the Versuch, (Quantz 1752, 46), he

appears to have been largely ignored, or misunderstood,

ever since. Tromlitz, perhaps because he felt the principles

of correct meantone tuning were so little heeded by

most musicians forty years on, places greater emphasis

on the subject, and gives us a more thorough explanation

(Tromlitz 1791, 65ff.). The two-keyed flute was considered,

at least by some, to be the most advanced and rational

form of the flute late enough to be included in the

Supplement to Diderot's Encyclopedie (Halfpenny

1956).

The headjoint tuning slide, a tenon and socket arrangement

in the headjoint to enable it to be pulled out to lower

the pitch, is associated with the name of Quantz. In

fact it was not new in the mid-eighteenth century: a

bass Renaissance flute by Jacopo Neni was made with

a tuning slide quite some time before the conical- bore

instrument was thought of (Young 1980, 30). By the end

of the eighteenth century, Tromlitz thought it a very

poor idea, as it would have the effect of enlarging

the headjoint bore at the point where the tenon was

pulled out, spoiling the flute's tone (Tromlitz

1791, 32). Late eighteenth-century English flutes by

Richard Potter (1726-1806) and others commonly had metal-lined

tuning slides in the headjoint, a device he patented

along with the pewter plug keys, graduated screw-cork

and register, and added keys, in 1785.11

Headjoints entirely lined with brass became

commonplace, especially in England, before the end of

the century, though German writers disapproved heartily

on account of the hardening effect on the flute's tone.

Fully-lined heads made it possible to make a tuning

slide only as thick as the metal itself, which minimised

the disturbance to the bore. Seamless thin-wall brass

tubing became generally available about 1800 (Sydenham

1979, 68); even after this makers fabricated their own

tubing by soldering a sheet of brass on a mandrel.

ADDITION OF KEYS

The history of lower extensions to the flute's range

and of the D# key shows that the addition of keywork

to the flute did not present any technical obstacles

which might have prevented still further keys being

added as far back as the 1720s. 12

But we have no evidence that any attempts were made

in this direction, except for the use of open-standing

keys on bass flutes to enable the player to reach the

very widely- spaced holes (Smith 1979, 4). Instead makers

seem to have been concentrating on finding exactly the

right combination of bore, wallthickness, tonehole spacing,

size and undercutting, to produce the results they wanted.

They must have believed that a solution to the few outstanding

problems of the flute existed in Nature and that such

a solution, though it was too complicated to be advertised

by any natural law such as the ones Lambert was seeking,

could be found by experiment. This view was still held

as late as 1811 by a man who was a both brilliant inventor

and had, ironically enough, become famous for his keyed

flutes. Saxon court instrument-maker Heinrich Grenser

believed that "the greatest art consists in building

flutes on which everything may be done without keys":

"Not in the multiplication of keys, no, in the

utmost simplicity of the flute, without sacrificing

anything to fashion, must this beautiful instrument

be brought to true perfection."13

The addition and acceptance of additional keys was a

complicated and gradual process, an accurate history

of which can only be approached when the history of

the one- and two-keyed flute is better understood than

it is today. Many professional wind players avoided

the new keys until the ends of their lives. They met

with resistance for many reasons (Burgess unpublished):

they do not make more slurs possible; they leak, and

can be hit by mistake; they may be useful for solos,

but orchestral parts are too easy to require them; and

finally--and this is a point which reminds us that the

flute is only a utensil for making music of whatever

kind--the player's technique must be of a level that

makes the instrument itself seem insignificant.

Ardal Powell is a partner with Catherine Folkers

in Folkers & Powell, makers of historical flutes,

and editor of the baroque flute newsletter, TRAVERSO.

He is a 1993-4 Fellow of the National Endowment for

the Humanities' program for Independent Scholars.

His study project is entitled "The Keyed Flute: Tehcnology

and Musical Style in the Late Eighteenth Century."

REFERENCES

Adkins 1990 Adkins, Cecil, "Oboes Beyond Compare: The

Instruments of Hendrik and Frederik

Richters", Journal of the American

Musical Instrument Society XVI (1990),

50-57

Baines 1965 Baines, Anthony, Woodwind Instruments

and their History, New York: Norton,

1957. Edition cited is: Rev. ed., 1965

Bate 1969 Bate, Philip, The Flute, London:

Ernest Benn, and New York: Norton, 1969

Blakey 1780 William Blakey, L'art de faire les

ressorts des montres, Amsterdam, 1780

Boehm 1871 Boehm, Theobald Die Flöte und das

Flötenspiel, 1871. Edition cited

is trans. by Dayton C. Miller as The

Flute and Flute-playing, New York:

Dover, 1964

Burgess unpublished Gustave Vogt, Méthode de

Hautbois, MS, Paris Conservatoire,

unpublished translation by Geoffrey

Burgess

Byrne 1964 Byrne, Maurice, "The Church Band at

Swalcliffe", Galpin Society Journal

XVII (Feb. 1964)

Byrne 1965 Byrne, Maurice, "Schuchart and the

Extended Foot-Joint", Galpin Society

Journal XVIII (March 1965), 7-13

Byrne 1983 Byrne, Maurice, "Pierre Jaillard, Peter

Bressan," Galpin Society Journal

XXXVI (March 1983), 2-28

Diderot 1781 Diderot, Denis Encyclopedie, ou

Dictionnaire Raissoné des Sciences,

des Arts et des Métiers,

Lausanne/Basel, 1781

Genta 1985 Genta, G., Kinetic Energy Storage:

Theory and Practice of advanced Flywheel

Systems, London: Butterworths, 1985

Giannini 1993 Giannini, Tula, Great Flute Makers of

France: the Lot and Godfroy Families,

1650-1900, London: Tony Bingham, 1993

Halbig 1924 Halbig, Hermann, "Die Geschichte der

Klappe und Flöten und

Rohrblattinstrumenten bis zum Beginn des

18 Jh.", Archiv für

Musikwissenschaft Leipzig: Fr. Kistner

& CFW Siegel, 1924

Halfpenny 1956 Halfpenny, Eric, "A French Commentary on

Quantz", Music & Letters XXXVII

(1956), 61-66

Heyde 1985 Heyde, Herbert, "Der Instrumentenbau in

Leipzig zur Zeit Johann Sebastian Bachs",

in 300 Jahre Johann Sebastian Bach

ed. Ulrich Prinz, Tutzing: Hans Schneider,

1985

Heyde 1993a Heyde, Herbert, "Die Werkstatt von

Augustin Grenser d. ä. und Heinrich

Grenser in Dresden", Tibia 4/1993

Heyde 1993b Heyde, Herbert, "Makers' Marks on Wind

Instruments", in William Waterhouse,

The New Langwill Index, London:

Tony Bingham, 1993

Karp 1978 Karp, Cary, "Woodwind Instrument Bore

Measurement", Galpin Society

Journal XXXI (1978), 9-31

Kirnbauer and Thalheimer 1995

Kirnbauer, Martin and Peter Thalheimer,

"Jacob Denner and the Development of the

Flute in Germany", Early

Music 23.1 (1995), 82-100

Kirnbauer 1992 Kirnbauer, Martin, "überlegungen zu

den Meisterzeichen Nürnberger

"Holzblasinstrumentenmacher" im 17. und

18. Jahrhundert", Tibia 1/92, 9-20

Lambert 1777 Lambert, Johann Heinrich, "Observations

sur les Flûtes", Nouveaux

Mémoires de l'Academie Royale,

Berlin: C.F. Voss, 1777

Landes 1983 Landes, David S., Revolution in Time:

Clocks and the Making of the Modern

World, Cambridge MA and London:

Belknap Press of Harvard University Press,

1983

Leutmann 1772 Johann Georg Leutmann,

Vollständige Nachricht von den

Uhren, Erste Continuation oder zweiter

Theil, Halle, 1772, Pt.2, Ch. 10

Loubet de Sceaury 1949 Paul Loubet de Sceaury, Musiciens et

facteurs d'instruments de musique sous

l'ancien régime, statuts

corporatifs, Paris: A. Pedone, 1949

McNeil 1990 McNeil, Ian, ed., An Encyclopaedia of

the History of Technology, London and

New York: Routledge, 1990

Mahaut 1759 Mahaut, Antoine, Nouvelle Méthode

pour Aprendre en peu de tems a Joüer

de la Flute Traversiere/Nieuwe Manier om

binnen korte tyd op de Dwarsfluit te

leeren speelen, Paris: Lachevardiere,

[1759] and Amsterdam: Hummel [1759].

Facsimiles by Geneva: Minkoff, 1972, and

Buren: Frits Knuf, 1989. Edition cited is

A New Method for Learning to Play the

Transverse Flute, trans. and ed.

Eileen Hadidian.

Bloomington and Indianapolis IN: Indiana

University Press, 1989

Majer 1732 Majer, Joseph Friedrich Bernhard Caspar,

Museum Musicum Theoretico

Practicum, Schwäbisch Hall: Georg

Michael Majer, 1732. Facsimile:

[Michaelstein]: Kultur- und

Forschungsstatte Michaelstein, 1991

Myers 1980 Myers, Herbert W., "The Practical

Acoustics of Early Woodwinds", D.M.A.

dissertation, Stanford University, 1980

Nettl 1951 Nettl, Paul, Forgotten Musicians,

New York: Philosphical Library, 1951

Nickel 1971 Nickel, Ekkehart, Der

Holzblasinstreumentenbau in der Freien

Reichsstadt Nürnberg, Munich:

Emil Katzbichler, 1971

Pierre 1893 Pierre, Constant, Les Facteurs

d'instruments de musique, les luthiers et

la facture instrumentale, Paris, 1893

Powell 1995 Powell, Ardal, "Die Eichentopf-Flöte:

Die älteste erhaltene vierteilige

Traversflöte?" Tibia 1/95

(1995).

An English

version, "The Eichentopf Flute:

the Earliest Surviving Four-joint

Traverso?", can be accessed on this web

site.

Powell and Lasocki 1995

Powell, Ardal with David Lasocki, "Bach

and the Flute: The Players, the

Instruments, the Music", Early

Music 23.1 (1995), 9-29

Prod'homme 1912 Prod'homme, J.G., ed., Ecrits de

musiciens, Paris, 1912

Puglisi 1984 Puglisi, Filadelfio, "A three-piece flute

in Assisi", Galpin Society Journal,

XXXVII (March 1984), 6-9

Quantz 1752 Quantz, Johann Joachim, Versuch einer

Anweisung die Flöte Traversiere zu

spielen, Berlin: Johann Friedrich

Voss, 1752. Edition cited is: On

Playing the Flute, trans. and ed.

Edward R. Reilly, Second edition, New

York: Schirmer Books, 1985

Rockstro 1890 Rockstro, Richard Shepherd, A Treatise

on the Construction the History and the

Practice of the Flute, London, 1890.

Reprint, 3 Vols., Buren NL: Frits Knuf,

1986

Sachs 1922 Sachs, Kurt, Sammlung alter

Musikinstrumente bei der staatlichen

Hochschule für Musik zu Berlin,

Berlin, 1922

Singer et al. 1957 Singer, Charles, E.J. Homlyard, A.R. Hall

and Trevor I. Williams, eds., A History

of Technology, 8 Vols., Oxford: OUP,

1957

Smith 1979 Smith, Catherine P., "Changing Use of the

Flute and its Changing Construction 1774-

1795", American Recorder XX.1 (May

1979), 4-8

Solum 1993 Solum, John, The Early Flute,

Oxford: Oxford University Press, 1993

Spohr 1992 Spohr, Peter, "Konische

Querflötenbohrungen��historiche

änderungen und musikalische

Auswirkungen", Bericht über das

10. Symposium zu Fragen des

Musikinstrumentenbaus, Michaelstein,

10.-11. November 1989, ed.

Eitelfriedrich Thom, Michaelstein, 1992,

39-47

Sydenham 1979 Sydenham, P.H., Measuring Instruments:

Tools of Knowledge and Control,

Stevenage and New York: Peregrinus, 1979

Toff 1979 Toff, Nancy, The Development of the

Modern Flute, New York: Taplinger,

1979

Tromlitz 1786 Tromlitz, Joahnn George, Kurze

Abhandlung vom Flötenspielen,

Leipzig: Breitkopf & Härtel, 1786

Tromlitz 1791 Tromlitz, Johann George,

Ausführlicher

und gründlicher Unterricht die

Flöte zu spielen, Leipzig: Adam

Friedrich Böhme, 1791. The edition

cited is: trans. and ed. Ardal Powell,

The Virtuoso Flute-Player,

Cambridge and New York: Cambridge

University Press, 1991

Tromlitz 1796 Tromlitz, Johann George, An das

musikalische Publikum, Leipzig, 1796

Tromlitz 1800 Tromlitz, Johann George, Ueber die

Flöten mit mehreren Klappen,

Leipzig: Adam Friedrich Böhme, 1800

Waterhouse 1993 William Waterhouse, The New Langwill

Index, London: Tony Bingham, 1993

Young 1980 Young, Phillip T., The Look of

Music, Vancouver [BC]: Vancouver

Museums and Planetarium Association, 1980

Young 1982 Young, Phillip T., Twenty-five Hundred

Historical Woodwinds, New York:

Pendragon Press, 1982

Notes

1Examples of the

need to understand contemporary tooling and methods

in the study of historical woodwinds are found in Karp

1978.

2Tromlitz 1786, referring

to Joseph Tacet (?-1801), London flutist.

3Solum 1993, 64, claims

Boie invented the pewter plugs. This seems to rely on

Rockstro 1890, para. 384, where the assertion

is made without citing a source. Boie's own attribution

to Tacet would seem to dispose of any possibility that

he may have invented them himself.

4Statuts, ordonnances,

lettres de création, arrests de sentence de la

communauté des maistres faiseurs d'instruments

de musique. De la ville et faubourgs de Paris. Paris:

Grou, 1741. Extensive documentation of Paris guild activity

is in Loubet de Sceaury 1949. See also Sentence de

Monsieur le Lieutenant General de police, rendé

en faveur de la communauté des ma�tres faiseurs

d'instrumens de musique. Contre la communauté des

ma�tres tabletiers. Du quatorze juillet 1741. Gilles

Lot obtained judgement in a 1752 lawsuit against Charles

Bizey, Thomas Lot, Paul Villars, Denis Vincent and Jacques

[de] Lusse, master instrument-makers, who had conspired

to prevent him being admitted as a master. G. Lot's

qualifications were: he had served 5 years as an apprentice

with Thomas Lot, his cousin, one year with Bizey, then

worked for Leclerc and married his daughter (Pierre

1893, 40-60).

5Inventory listings

are given by Marcelle Benoit and Norbert Dufourcq in

various volumes of "Recherches" and in Giannini

1993

6"Mémoire de M.

de la Barre: sur les musettes et hautbois &c.",

cited in Prod'homme 1912, 244. The wind-instrument playing

families of Philidor and especially Hotteterre are still

given credit by most modern writers with having invented

the conical-bore flute at about the same time as the

oboe was developed, largely on the strength of de la

Barre's testimony. But we are to rely on his statement

at all we must actually rule out this possibility, for

it continues:

From that time on, bagpipes were left to shepherds;

violins, recorders, theorboes and viols took their

place--for the transverse flute did not come along

until later.

Thus de la Barre did not credit any member of the Hotteterre

family with introducing the baroque flute, and does

not himself seem to know where it came from.Quantz (Quantz

1752, I.5) merely guesses that the flute underwent the

same changes as the oboe and bassoon at the same time

and place; and he only guesses after admitting that

"who its originator was cannot be fixed with certainty,

although I have spared no pains to discover reliable

answers."

7"Herrn Johann Joachim

Quantzens Lebenslauf, von ihm selbst entworfen",

in F.W. Marpurg, Historisch-critisch Beyträge

zur Aufnahme der Musik, I (1755), 197-250. Translated

in Nettl 1951.

8 Byrne 1965. Toff 1979,

25- 6, mistakenly asserts that Florio, Gedney and Richard

Potter revived the lower extension "in about 1774".

This piece of conjecture seems to have originated with

Baines 1966, 294. But it is contradicted not only by

the Mason and Gedney announcments of 1756 cited in Byrne

1965, but also by the existence of the Gedney flute

dated 1769 mentioned above and in Bate 1969, 97.

9 SeePowell and Lasocki

1995. 40% of the German 3-joint flutes surviving

to this century had a C-foot. An advertisement appeared

as late as 1748 for what seems to be a flute with a

C-foot: "A Denner traverso in ivory, with gilded keys

[sic], can be had together with its case lined with

red cloth" (Kirnbauer and Thalheimer 1995). In the thinly

veiled piece of sales propaganda headed "Newly invented

means for the improvement of the flute" [Neu erfundene

Vortheile zur bessern Einrichtung der Flöte] in

Tromlitz 1786, Tromlitz says he used to make foot extensions

to low C twenty or thirty years before, but gave up

as they did not become popular in Germany owing to their

detrimental effect on the flute's tone.

10Quantz 1752, 31. Quantz

has been followed by nearly all subsequent authors.

11Rockstro 1890,

para. 473. Almost certainly, none of these was Potter's

own invention.

12Halbig 1924. On

p.43 Halbig cites a Sourdeline depicted in Mersenne's

Harmonie Universelle II, Proposition XXX, 293ff.,

having an extensive system of closed chromatic keywork.

A similar system was used on the musette, popular at

the French court in the seventeenth and eighteenth centuries.

Smith 1979 points out that the Hotteterres were making

heavily keyed musettes at the same time as they were

(supposedly) contributing to the genesis of the baroque

flute.

13Nicht in der Anzahl

der Klappen, nein, in der möglichsten Einfachheit

der Flöte, ohne Eleganz etwas aufzuopfern, muss

die wahre Vervollkommung dieses schönen Instruments

gemacht werden. H. Grenser, letter to Allgemeine

Musikalische Zeitung 46, 13 November, 1811, col.775.

|